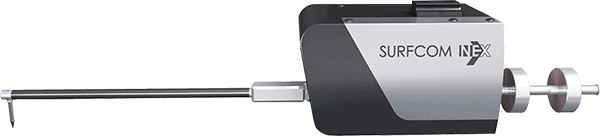

SURFCOM NEX 040

The SURFCOM NEX 040 is suitable for measuring high precision contour geometries such as ball spindles or ball bearings in manual or CNC controlled measurement procedures.

Contour probe head with a glass scale, with 0.02 µm resolution using the full measurement range

Z measuring range for 60 mm contour

Standard measurement precision ±(0.8+|2H|/100) µm

Automatic setting of the probing force, software-controlled in 2mN steps

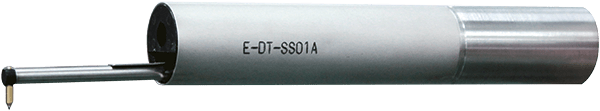

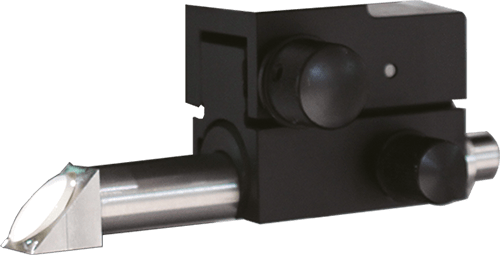

Quicker change of probe arm with a positioning magnetic holder (patented)

Probe head geometries are compensated from the software side

Z measuring range for 60 mm contour

Standard measurement precision ±(0.8+|2H|/100) µm

Automatic setting of the probing force, software-controlled in 2mN steps

Quicker change of probe arm with a positioning magnetic holder (patented)

Probe head geometries are compensated from the software side

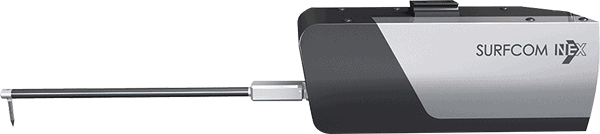

Surveys and measurements for determination of the diameter are possible with a T stylus

- Fully CNC controlled with teach-in programming

- High traversing speed: X-axis (horizontal) 100 mm/s, C-axis (vertical) 50 mm/s

- Modular structure with sensors for different applications

- Low vibration ensures more stable measurements at high resolution

- Low maintenance thanks to contactless linear drive

- Safety system prevents collisions with the workpiece

- Comprehensive and user-friendly evaluation software

- All instruments available with anti-vibration table (DX version)

- Automated measurement procedures thanks to CNC positioning tables (optional)

Area of application

The SURFCOM NEX 040 is suitable for measuring high precision contour geometries such as ball spindles or ball bearings in manual or CNC controlled measurement procedures.