You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

Metal chips occur between the tool holder and spindle cone, and cause abnormal run-out.

Solution

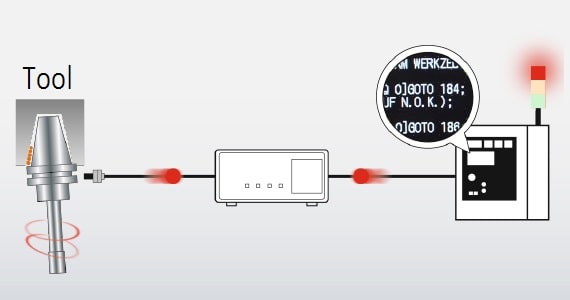

“ATC Sensor identifies runout in 0.3 seconds.

Controller triggers the machine stop function.”

Quality aspect in metal finishing

Measuring result in 0.3 seconds

High precision identification within 5 µm

Simple installation

Workpiece examples: cylinder blocks, cylinder heads, transmission case, compressor cases, ABS parts, rocker arms, hybrid cases, medical and fine mechanical components

Tools: reamer, boring tool, milling cutter, etc.