Eumetron GmbH – Global spearhead in the calibration of reference standards using RONDCOM

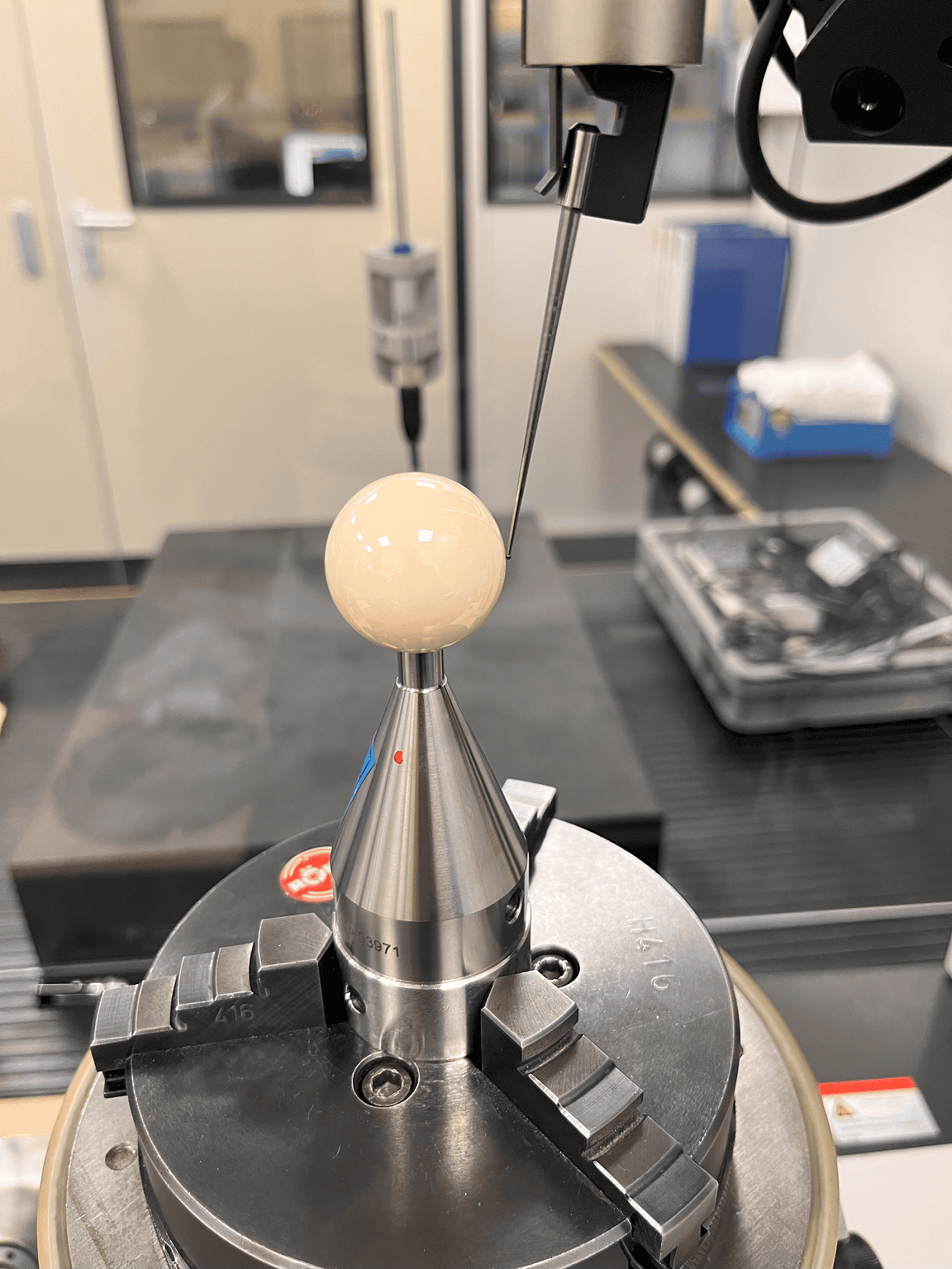

The DAkkS-accredited laboratory of eumetron GmbH in Aalen, Germany offers DAkkS calibrations traceable to national standards with an extremely high level of accuracy that is unrivalled worldwide. The experts use special procedures to calibrate plug gauges, setting rings, calibration spheres and hemispheres as well as test specimens and other reference standards or reference workpieces. Standards are used to adjust, calibrate, check and set dimensional measuring systems and are therefore important tools in quality assurance. When it comes to roundness measurement, eumetron GmbH relies on two RONDCOM form measuring devices from ACCRETECH. In doing so, eumetron GmbH achieves measurement uncertainties of just ten nanometres.

Quality assurance is indispensable for practically all industries. And length measurement technology is at the centre of quality assurance in most manufacturing industries and their service providers. Exact dimensional accuracy in accordance with specified tolerance values must be guaranteed to ensure perfect usability, function, reliability and durability of the workpieces. Testing and compliance with tolerances, taking measurement uncertainty into account, is the task of quality assurance using a wide variety of length measuring devices, which must be subjected to a calibration process on a regular basis. Deviations due to geometric errors, thermal influences or deviations in shape and position cause measurement deviations that are different at every point in the measurement volume. By comparing current production with reference workpieces, changes in the production process can be recognised at an early stage.

Such dimensional measuring systems include, for example, coordinate, form, contour, height and surface roughness measuring devices, as well as profile and measuring projectors, but also measuring microscopes, computer tomographs, laser trackers, fringe light projection and photogrammetry systems.