Explaining the reason for the RONDCOM NEX purchase, European Quality / Warranty Manager at HydraForce Birmingham, Ali Mohammed said. “We manufacture a comprehensive line of high-quality hydraulic valves and manifold systems. Our products meet global quality standards including ISO 9001 and QS 9000. To confirm that they perform beyond industry standards our hydraulic products go through rigorous testing and inspection routines. Also, to ensure global consistency, the teams at HydraForce plants in North America, Brazil, Asia, and here at our Birmingham European headquarters, follow the same manufacturing processes and standards.”

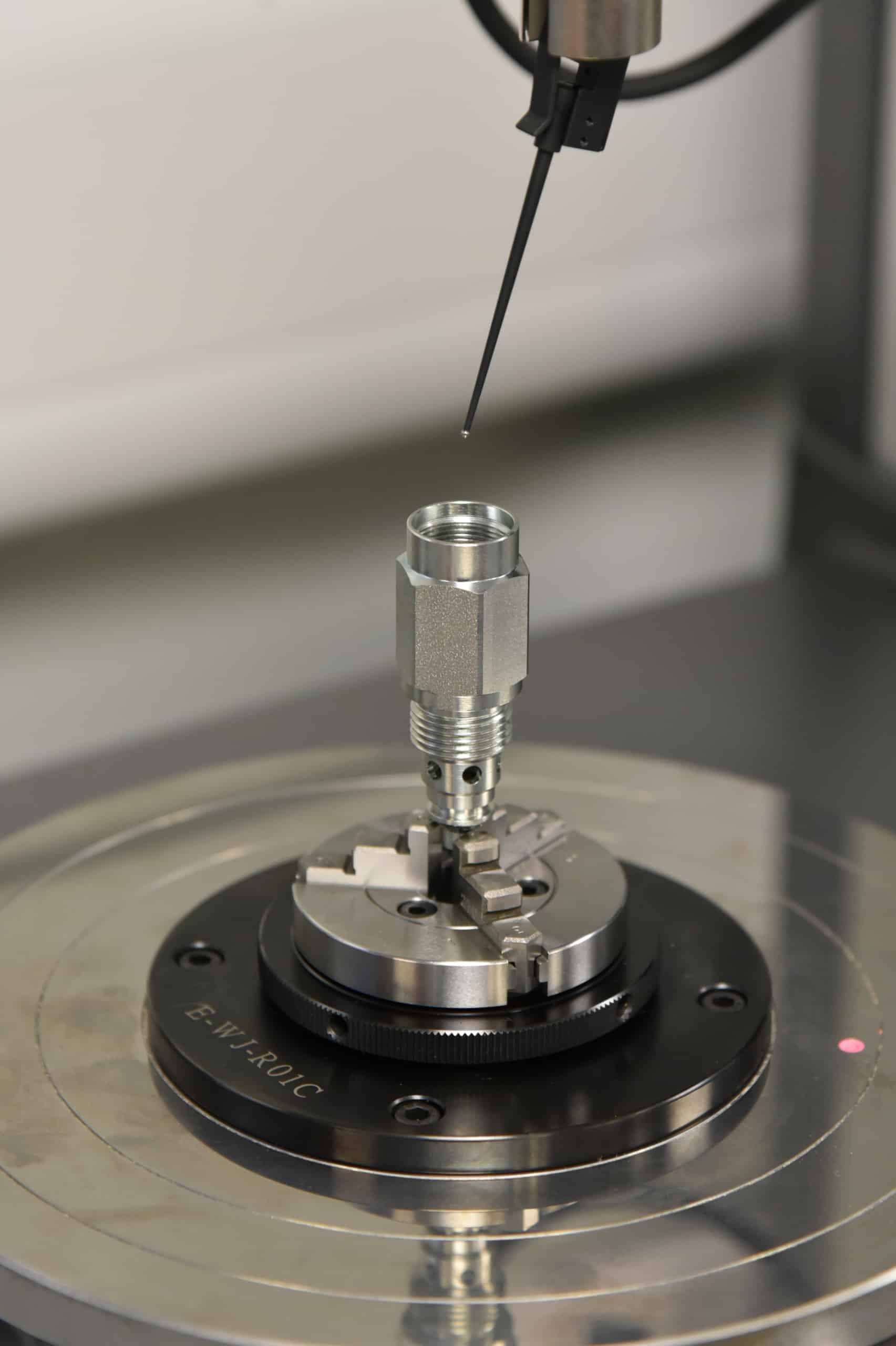

“The bores in the high-precision hydraulic manifolds manufactured by HydraForce Birmingham have extremely challenging geometrical tolerances. Parameters checked include roundness, roughness, cylinder form, perpendicularity, parallelism, straightness, flatness, coaxiality and concentricity. All of these attributes need to be inspected to an extremely high degree of accuracy.”

“We have recently increased the number of European suppliers we deal with and reduced the amount components we import from our US plant. As all of the parts previously sent from our North American operation arrived in a fully inspected condition, to enable all brought-in European components to be 100% inspected we needed to increase our quality control capacity in the critical area of highly precise bore geometry measurement.”

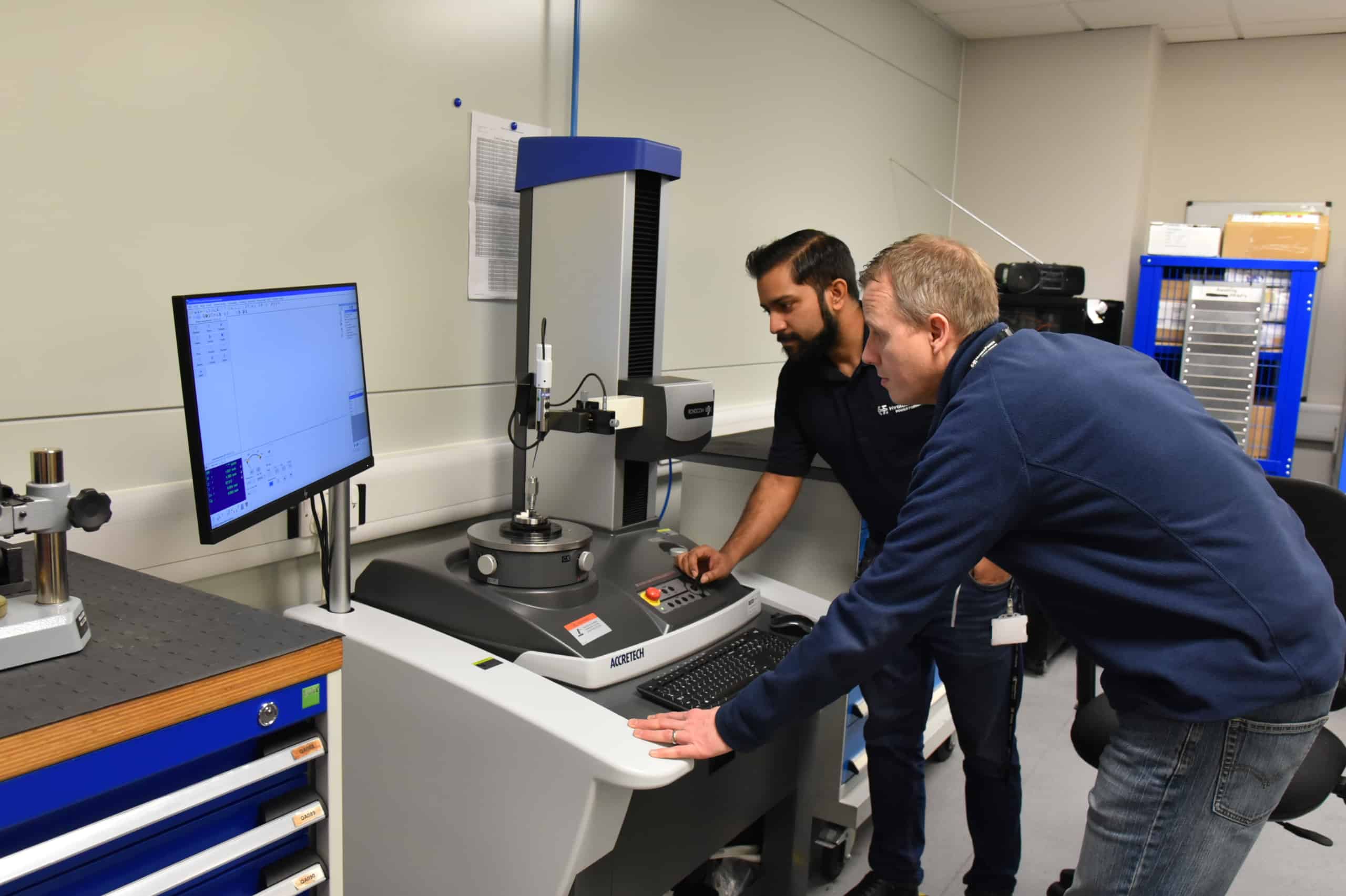

“This situation was further compounded as we have recently considerably increased our bore honing capacity. To help overcome these potential difficulties I searched for a suitably accurate and efficient profile measuring instrument. Having studied the available models from three leading metrology manufacturers I came to the decision that Accretech’s advanced RONDCOM NEX CNC instrument was the most capable option.”

“In addition to the precision of our measuring equipment being important, given the high-volume of components now passing through our busy inspection department, the speed and ease of use of our quality control equipment is also crucial to the department’s efficient operation. Therefore, it helped my profile measuring instrument decision that, in addition to delivering the required high-precision standards, the RONDCOM NEX’s rapid, fully automated CNC measuring procedures provided the desired operational efficiency standards.”

“As the RONDCOM NEX is relatively easy to operate, following operator training our new ACCRETECH profile measuring instrument soon proved its high-precision capabilities across all bore parameters. As we are now able to quickly recall pre-written programs and start fast, highly-accurate bore inspection routines, our RONDCOM NEX is now making a significant contribution to the efficient operation of our quality department.”